BLP Racing Carburetors

BLP Racing Carburetors

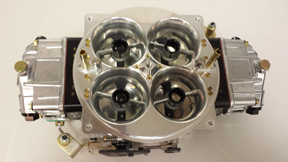

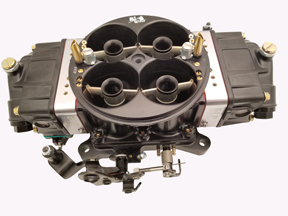

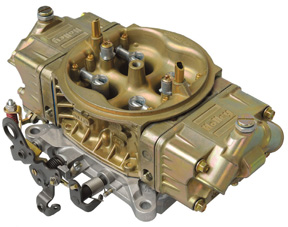

BLP BILLET XTREME SERIES RACING CARBURETORS

Today every form of motor racing enjoys a tremendous growth in popularity, increased competition, and a higher degree of technological advancement. The performance products manufacturers who support this growth must continue to develop and improve their products to provide a competitive edge.

In the last few years, BLP has focused on improving development on their BX (Billet Xtreme) Series applications. With our continued focus on on-track development, we are better able to understand the engine requirements and carburetor needs of our customers. Our Revolution engine dyno facility was designed to provide accurate data needed for research and development work.

.

Allow us to help you gain the most from your application download our Carb information form

These key combinations and over 40 years of racing experience give us a definite advantage when choosing the right fuel system for your application. BLP Carburetors are designed to perform the necessary functions to be competitive in today’s hi-tech racing. Every BLP Carburetor has been selected and modified to provide easy starting, good clean idling, smooth R.P.M. transition, and efficient wide-open throttle operation.

Rated Air Flow vs. Rated Wet Air Flow.

At BLP we feel it is most important that our customers understand how carburetors are airflow tested on a flow bench and how our rated CFM flow figures are calculated. Carburetors can be airflow tested by (2) methods: Dry Air Flow and Wet Air Flow.

Dry Air Flow testing represents the total amount of air drawn through the carburetor without taking into consideration the amount of air that the fuel being used displaces at a given ratio. This is the most common way of testing and represents the advertised CFM figures that you see Holley® use for their new carburetors as well as carburetor modifiers for their modified carburetors. To be consistent we use this method to flow test our carburetors.

Wet Air Flow testing represents the total amount of air drawn through the carburetor less the amount of air the fuel being used displaces or in simpler terms the net amount of CFM the engine recognizes. To figure wet airflow you need to subtract the amount of air the fuel displaces from the dry airflow CFM number. If you would like to calculate the wet airflow in your application we have furnished you with the following formula:

The following A/F ratios are utilized in calculating rated airflow for different fuel types and applications:

Racing Gas 7.6%

Marine 8.3%

Methanol 16.7%

You will notice when choosing a methanol carburetor that the wet airflow CFM rating will be lower than the same carburetor using racing fuel. This is because methanol displaces more of the airflow than racing gas causing the wet airflow CFM to be lower even though the carburetor is the same physical size.

Carburetors are Dry Air Flow tested at 20.4” on a SuperFlow SF-1200 FlowCom flow bench using a 2” open hole spacer.

Today every form of motor racing enjoys a tremendous growth in popularity, increased competition, and a higher degree of technological advancement. The performance products manufacturers who support this growth must continue to develop and improve their products to provide a competitive edge.

In the last few years, BLP has focused on improving development on their BX (Billet Xtreme) Series applications. With our continued focus on on-track development, we are better able to understand the engine requirements and carburetor needs of our customers. Our Revolution engine dyno facility was designed to provide accurate data needed for research and development work.

.

Allow us to help you gain the most from your application download our Carb information form

These key combinations and over 40 years of racing experience give us a definite advantage when choosing the right fuel system for your application. BLP Carburetors are designed to perform the necessary functions to be competitive in today’s hi-tech racing. Every BLP Carburetor has been selected and modified to provide easy starting, good clean idling, smooth R.P.M. transition, and efficient wide-open throttle operation.

Rated Air Flow vs. Rated Wet Air Flow.

At BLP we feel it is most important that our customers understand how carburetors are airflow tested on a flow bench and how our rated CFM flow figures are calculated. Carburetors can be airflow tested by (2) methods: Dry Air Flow and Wet Air Flow.

Dry Air Flow testing represents the total amount of air drawn through the carburetor without taking into consideration the amount of air that the fuel being used displaces at a given ratio. This is the most common way of testing and represents the advertised CFM figures that you see Holley® use for their new carburetors as well as carburetor modifiers for their modified carburetors. To be consistent we use this method to flow test our carburetors.

Wet Air Flow testing represents the total amount of air drawn through the carburetor less the amount of air the fuel being used displaces or in simpler terms the net amount of CFM the engine recognizes. To figure wet airflow you need to subtract the amount of air the fuel displaces from the dry airflow CFM number. If you would like to calculate the wet airflow in your application we have furnished you with the following formula:

The following A/F ratios are utilized in calculating rated airflow for different fuel types and applications:

Racing Gas 7.6%

Marine 8.3%

Methanol 16.7%

You will notice when choosing a methanol carburetor that the wet airflow CFM rating will be lower than the same carburetor using racing fuel. This is because methanol displaces more of the airflow than racing gas causing the wet airflow CFM to be lower even though the carburetor is the same physical size.

Carburetors are Dry Air Flow tested at 20.4” on a SuperFlow SF-1200 FlowCom flow bench using a 2” open hole spacer.